Proper traffic cone placement is a critical safety measure that protects workers, drivers, and pedestrians alike. However, the exact distance between two adjacent cones depends on several factors, like road type, traffic speed, and highway lanes.

In this article, we break down the complex topic of traffic cone spacing into simple terms to ensure safe, effective, and fully compliant job-site setups.

Traffic Cones & Channelizing Devices

Traffic cones are part of a group called channelizing devices, which are used for various traffic control applications. They are used for controlling traffic during road construction, maintenance, accidents, events, and other road emergencies.

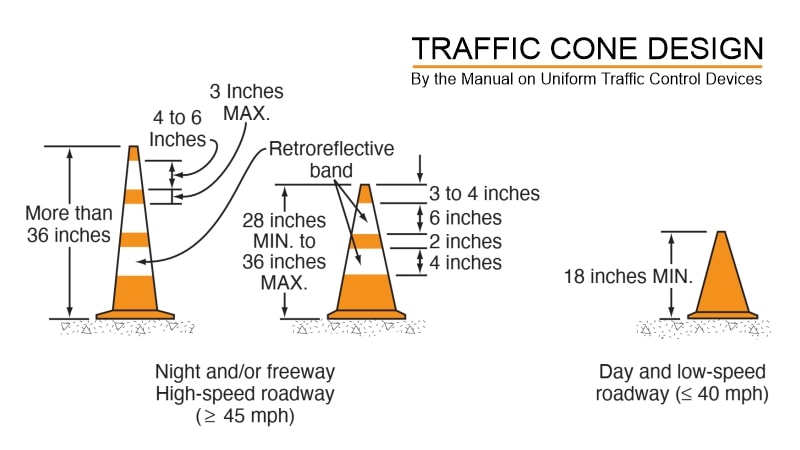

The size and design of traffic cones aren’t strictly controlled. Instead, there are general guidelines for cone designs based on application.

Table 1 – Size and design guidelines for traffic cones.

| ConeSize | ReflectiveBands | ConeHeight | BandSize | BandSpacing | Application |

| Small | Not Required | >18 inches | – | – | Daytime & Low-Speed Roadways |

| Medium | Required | 28-36 inches | 4-6 inches | 2 inches | Nighttime, Freeway, or High-speed Roadways |

| Large | Required | >36 inches | 4-6 inches | 3 inches | Nighttime, Freeway, or High-speed Roadways |

Smaller cones are not required to have white reflector bands. However, all traffic cones should be bright orange for maximum visibility.

Other traffic channelizing devices include tubular markers, drums, vertical panels, and road barricades. Guidelines for all devices are outlined in the Manual on Uniform Traffic Control Devices (MUTCD) by the US Federal Highway Administration.

Importance of Traffic Cones

Traffic cones play a vital role in ensuring road safety for vehicles and pedestrians alike. Here is a short list highlighting the importance of proper cone placement.

1. Traffic Management

With proper placement of cones, construction workers can better manage traffic flow during rush hours. Traffic cones set a clear path for drivers and divert traffic to alternate routes in case of a complete lane closure.

2. Create Secure Work Zones

Traffic cones mark hazard areas by forming a boundary around hazard areas and warn drivers well ahead of time. During parades and events (concerts, marathons, or cycling competitions), strategic cone placement creates a safer environment for all participants.

3. Safer Environments

Traffic cones create safer environments for everyone, especially site workers who are the most at risk of car accidents, and traffic cones ensure their safety. Cones also reduce the risk of secondary accidents.

4. Prevent Unauthorized Access

Traffic cones also prevent unauthorized access to accident areas and construction sites. Cones establish a no-entry zone to discourage people from interfering with the work site.

Road types determine the exact cone placement and spacing. Highways require cones to be placed further apart and cover a larger area around the work site. Urban areas require more cones for the same amount of road space.

Traffic Cone Placement Distance on Highways

Traffic cones placement is decided by a series of mathematical formulas depending on highway conditions. The MUTCD is the authority when it comes to traffic cone placement. OSHA standards also directly cite the MUTCD for workplace safety regulations.

It states that the maximum distance between two cones should be 1 times the speed limit for taper channelization and 2 times the speed limit for tangent channelization. There is no minimum distance requirement, so you can place cones as close to one another as needed.

At this point, some of you may be confused by the terms taper and tangent. So, let’s break down these terms into more understandable words.

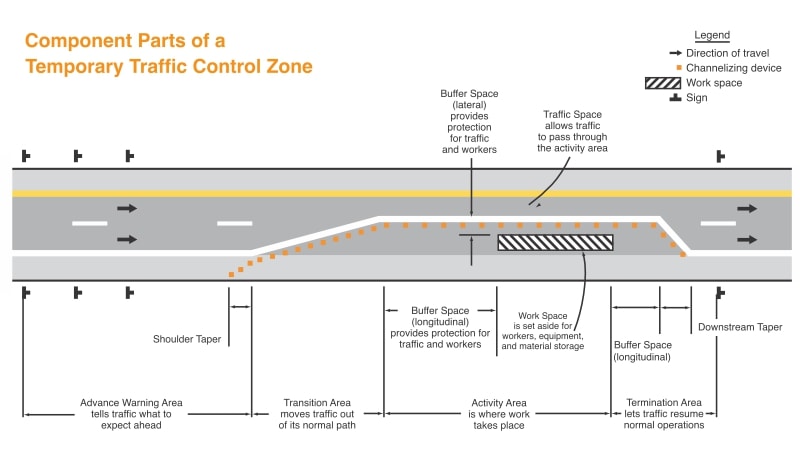

Taper Distance

Taper is the placement of channelizing devices (traffic cones) before and after the work zone. They act as advance warning signs for upcoming construction zones, heavy traffic areas, and accident sites.

When closing off a lane, you are required to slowly direct traffic to the other lanes. In order to do so, cones are placed at an angle from one side of the lane to the other, for maximum visibility. There are two types of tapers.

- Upstream Taper: When traffic is driving towards the work zone.

- Downstream Taper: When traffic is driving away from the work zone. (optional but helpful)

You can calculate the upstream taper distance using the following formulas.

Table 2 – How to calculate taper length for traffic cone placement.

| Highway Speed Limit (S) | Taper Length (L) in Feet |

| 40 mph or less | L=W*S*S/60 |

| 45 mph or more | L=W*S |

- L = Taper Length (in Feet)

- W = Width of Work Zone (in Feet)

- S = Speed Limit (in Miles per Hour)

Tangent Distance

Tangent refers to the cone placement parallel to the moving traffic. It covers the work zone and the buffer area. Unlike taper areas, where cones are placed at an angle. Here cones are placed in a straight line.

Activity Area = Work Zone + Buffer Zone

Buffer zones significantly reduce the chances of secondary accidents. They protect responders, construction workers, and drivers.

Although there are no specific rules for buffer zone sizes, the MUTCD recommends a minimum of 155ft. of buffer area before a work zone.

Buffer zones also create safe parking spaces for emergency vehicles like police cars, ambulances, and fire trucks.

Traffic Cone Spacing

Using all of the above information, we can now establish a simple system for traffic cone placement. You should space cones equally, even if it’s not a strict requirement.

Table 3 – Traffic cone spacing guideline for Highways by MUTCD.

| Traffic Cone Spacing(Manual on Uniform Traffic Control Devices) | |||

| HighwaySpeed Limit | Taper AreasMAX. Cone Spacing | Tangent AreasMAX. Cone Spacing | Downstream Taper(50-100 ft.) |

| 20 mph | 20 ft. | 40 ft. | 20 ft. |

| 30 mph | 30 ft. | 60 ft. | 20 ft. |

| 40 mph | 40 ft. | 80 ft. | 20 ft. |

| 50 mph | 50 ft. | 100 ft. | 20 ft. |

Source: 11th Edition of the “Manual on Uniform Traffic Control Devices“, Section 6K.01 Channelizing Devices – General, Page 815.

Note: These are broad guidelines as per the MUTCD. However, you should always check your local regulatory bodies.

For example, the Standard Plans for Road Construction, as outlined by the Florida Department of Transportation (FDOT), argues that traffic cones should be no more than 25 feet apart regardless of highway speeds.

Table 4 – Traffic cone spacing guideline for Highways by FDOT.

| Placing Traffic Cones(Standard Plans by the Florida Department of Transportation) | ||

| HighwaySpeed Limit | Taper AreasMAX. Cone Spacing | Tangent AreasMAX. Cone Spacing |

| <45 mph | 25 ft. | 50 ft. |

| >50 mph | 25 ft. | 50 ft. |

Source: “General Information for Traffic Control Through Work Zones” by FDOT Standard Plans Index 102-600.

Cone Placement in Urban Areas

Urban areas refer to city streets and other slow-speed traffic areas. There are no real guidelines for traffic cone placement distance in small city streets.

Construction workers are expected to secure the work area through adequate cone placement. The number of cones needed and their placement depend on the nature of the work zone.

Certain job sites only occupy a few feet of a single-lane road. The MUTCD rules don’t help here because if the work zone is only 15 feet long, then placing cones 20 feet apart is impractical.

Instead, it focuses on the weight of the cones. Urban construction sites should use heavier cones so they can withstand winds at high speeds.

For two-lane roads, the cone layout should be designed such that only one lane is closed. The space between cones should be small so that a car doesn’t accidentally enter the work area.

Table 5 – Traffic cone spacing guideline for Urban Areas.

| Traffic Cone Spacing for City Streets | ||

| CitySpeed Limit | Taper AreasMAX. Cone Spacing | Tangent AreasMAX. Cone Spacing |

| <20 mph | 5-10 ft. | 10-20 ft. |

| >25 mph | 10-15 ft. | 10-20 ft. |

The above-mentioned data is extracted based on the guidelines from the MUTCD and the general requirements of intercity construction sites.

Remember, there is no minimum distance requirement for cone placement. So, we recommend using additional cones to cover as much of the job site as possible to ensure maximum visibility.

5 Tips for Placing Traffic Cones

Here are some quick tips to help you ensure construction site security and driver safety.

1. Always Face Oncoming Traffic

Drivers don’t always follow speed limits, and it puts workers at risk. Always face traffic when placing cones on roads and highways. So in the unlikely event that vehicles don’t slow down, the worker has enough time to move aside.

2. Use an AFAD When Possible

An Automated Flagger Assistance Device (AFAD) is road safety equipment with an attached 12-inch red flag. When the flag is down, it signals the incoming drivers to stop and wait for the flag to go up. AFADs significantly reduce the risk of accidental crashes and keep workers safe.

3. Maintain Proper Cone Spacing

Traffic cones should be evenly spaced around the work site to clearly guide drivers and pedestrians alike. Gaps in the cone spacing may give the false impression that it’s now ok to merge into the lane.

4. Always refer to the MUTCD Guide

There are several things we cannot cover in a quick article. Therefore, workers should always keep a copy of the MUTCD on hand. You can download it for free from the Federal Highway Administration’s website (FHWA). It has specific guidelines for two-lane roads and how to guide traffic to change lanes on highways.

5. Advance Warning Using Road Safety Signs

MUTCD standards require the use of several road safety and warning signs before cone placement. These signs tell drivers that the road ahead is closed for construction and to change lanes. The distance legend on the road signs can be either XX feet, XX miles, or simply “Ahead”.

Example: Road closed in 200 feet.

Conclusion

Whether it’s road maintenance on a busy highway or a construction site on a small city street, proper placement of traffic cones plays a big role in keeping drivers and workers safe. There is no minimum spacing requirement for traffic cones, but there is a maximum spacing requirement. Use this guide to plan your cone layout for your next construction site.

Get Durable & Long-Lasting Traffic Cones from Manywell!

Manywell is a leading manufacturer of cleaning and safety supplies. Our diverse product catalog includes microfiber towels, mop accessories, andtraffic cones. You can customize the size and weight of traffic cones according to your local regulations.

Take advantage of our competitive pricing and get a Free Quote Today!